- Submissions

Full Text

Aspects in Mining & Mineral Science

Abrasive Ability of Staurolite Mineral Concentrate Produced by Vilnohirsk Mining and Metallurgical Combine

Vladimir Poltoratskiy1* and Olga Leshchenko2

1 Department of physical-chemical principles of formation of super hard and nanostructured materials, Ukraine

2 Institute of Super hard Materials, Ukraine

*Corresponding author: Vladimir Poltoratskiy, Department of physicalchemical principles of formation of super hard and nanostructured materials, V Bakul Institute for Super hard Materials, National Academy of Sciences of Ukraine, Ukraine

Submission: February 22, 2019;Published: March 26, 2019

ISSN 2578-0255Volume2 Issue5

Abstract

The abrasive ability of a staurolite mineral concentrate of 160/100 grain size produced by Vilnohirsk Mining and Metallurgical Combine is determined and comparative data of the abrasivity of AC6 125/100 synthetic diamond powder is indicated. (Grinding powders of such grain size are most often used in abrasive grinding tools and pastes). The results of our studies of the abrasiveness of staurolite concentrate samples have shown that the staurolite can be used in compositions for the production of special types of tools and pastes intended to achieve high-quality surface treatment.

Keywords:Abrasive ability; Staurolite; Synthetic diamond; Grinding tools; Abrasive pastes.

Introduction

Titanium-zirconium minerals are natural mineral raw materials that have abrasive properties. The minerals are processed products of titanium-zirconium ore. Recently, extraction and enhancement of the quality of concentrates (Rutile, Staurolite, Ilmenite, Zircon and Distan-Silanite) has been considerably increased at the Vilnogirsk Mining and Metallurgical Combine (Dnipropetrovsk region, Ukraine). Due to relatively low cost of raw produce, these concentrates are in great demand in Ukraine and abroad.

The abrasive properties of the staurolite mineral are well known, especially for sandblasting processes. Staurolite is a general-purpose mined mineral abrasive used to remove thin coatings, rust, and mill scale. Its sub-angular shape is ideal for applications where a minimal surface profile is required. Staurolite is excellent for achieving a near white finish and is commonly used for new steel applications; including storage tank and tower construction, structural and plate steel blasting, and steel fabrication [1-3].

Materials, Equipment and Experimental Technique

The object of the study is a powder of staurolite concentrate produced by the Vilnogirsk Mining and Metallurgical Combine. The mineralogical composition of a staurolite concentrate is: staurolite -81-86%; kyanite, Sillimanite- 0.5-1.5%; Ilmenite- 5-7%; Zircon - 1-1.5%; Tourmaline- 7-10%; Quartz -0.1-0.5%. The samples of the staurolite concentrate produced by the Vilnogirsk Mining and Metallurgical Combine contain: TiO2+Al2O3-50.60%, SiO2-27.8%. Staurolite concentrates belong to a group of granular concentrates of medium strength (Destructive loading -2.8-3.0N). Staurolite is a mineral of a class of silicates, an island silicate of aluminum and iron with additional anions. The chemical composition of the staurolite mineral -Fe2+2Al9O6(SiO4)4(O, OH)2 [4]; Mohs scale hardness - 7-7.5; density - 3.7-3.8g/cm3.

The strength of the staurolite of Vilnohirsk ore deposits of grain size 200/160 -4.3N, 160/125- 3.4N; Mohs scale hardness -7.5; density - 3.7g/cm3; bulk density (without shaking)-2.0, Bulk density (with shake) -2.25; the coefficient of fluidity -0.71; the specific surface -9.018 m2/g; form factor (Kf) -1.38; the coefficient of isometry -0.72.

In order to expand the scope of both staurolite, staurolite concentrate and mixed with super hard materials (Diamond, cubic boron nitride) for the manufacture of abrasive grinding tools we studied the abrasive ability of staurolite concentrate produced in Vilnohirsk. The possibilities of using granular mineral concentrates in a diamond-abrasive tool are shown in [5]. In this paper we pay attention to same on granular staurolite concentrates.

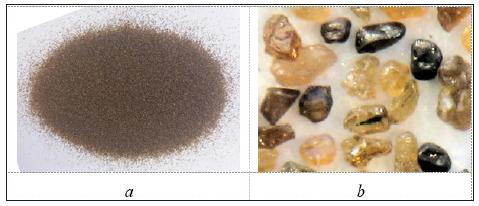

When examining the samples of material, it is clear that the staurolite concentrate is a mixture of grains of different sizes (250-100μm) and different colors (brownish and yellow-orange shades of color of natural amber, black) (Figure 1). Determination of abrasive ability of samples of staurolite concentrate powder was carried out on the UAS-2M equipment (design of the ISM, NASU) according to the “Method for determining the abrasive ability of grinding powders of synthetic diamonds using a special grinding composition” (М 28.5-267: 2006 test procedure standard of ISM, NASU).

Figure 1:General view of the staurolite concentrate sample (a), grains of the material (b)..

The essence of the method is to determine the mass difference of samples of hard alloy (or ball bearing steel) before and after grinding by diamond grinding powder (as a base component of a special grinding composition) on the UAS-2M equipment during 20min. The UAS-2M equipment is a table-top flat surface grinder with a horizontally positioned 22HC* ceramic faceplate, the diameter of the faceplate is 110mm.

Characteristics of the working process in determining the abrasive ability of the dispersed material:

A. Faceplate rotation speed-100rpm;

B. Frequency of double movement on the faceplate of holder with samples of materials that are processed with test dispersed material -60 min-1;

C. Holder movement-50mm;

D. Mass of the load that presses down to the faceplate the samples of material that are processed by test dispersed material- 2kg;

E. Duration of the work cycle for determining the abrasive ability of the dispersed material samples -20min.

The samples, by means of which the abrasive ability of the dispersed material is determined, are cylinders with diameter of 11 mm and height of 10mm, the cylinders are made of ShH15** ball bearing steel or WC 6*** hard alloy. The grinding composition with the test dispersed material is evenly distributed on the faceplate surface. The samples-cylinders fixed in the holder are pressed down to the faceplate by load of 20N and the process of determining abrasive ability of the dispersed material begins. Then the mass difference of samples-cylinders before and after grinding by tested dispersed material should be valued.

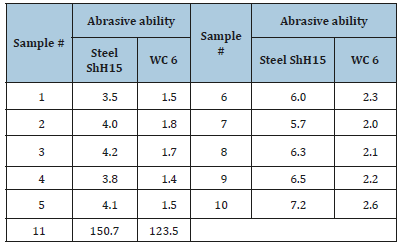

According to the test procedure standard each sample of a dispersed material is tested twice. Abrasive ability value of a dispersed material sample is arithmetical mean value of results of the testing. The results of the determining the abrasive ability of the samples of staurolite concentrate are shown in the Table 1. As a standard of reference, the value of abrasive ability of AC6 125/100 synthetic diamond powder (DSTU 3292-95 standard) is also indicated (Sample#11). Thus, the abrasive ability of Vilnohirsk staurolite concentrate for ShH15 steel is 5.08±1.21 - for comparison the abrasive ability of AC6 125/100 synthetic diamond powder is 150.7. The abrasive ability of Vilnohirsk staurolite concentrate for WC 6 hard alloy is 1.89±0.38- for comparison the abrasive ability of AC6 125/100 synthetic diamond powder is 123.5.

Table 1:Abrasive ability of the staurolite concentrate.

Stavrolite concentrate grains have a mostly rounded isometric shape with a polished surface, for grains of all factions Kf=1.35- 1.46. But after further sorting the material on the vibration tables, it will be possible to extract fractions of the grains with a more rounded form (Kf ≈1), that will be possible to find a new areas of use of staurolite concentrate as well as the mixtures of staurolite and high-strength diamond powders of the AC200 grade, especially in the grinding-cutting and drilling tools.

The abrasive ability of specially made ointment-like abrasive pastes containing staurolite was also determined (Table 2). The paste base is a universal one (Vaseline, stearin, oleic acid, emulsion wax), therefore the pastes are washed with organic solvents (Gasoline, Alcohol, Kerosene).

Table 2:Abrasivity of abrasive pastes containing staurolite.

Conclusion

The results of our studies of stavrolite concentrate samples have shown that the staurolite concentrate can be used in compositions for the production of special types of tools and pastes intended for treatment of surface, to obtain surface treatment of a higher level. After further sorting the material on the vibration tables, it will be possible to extract fractions of the grains with a more rounded form (Kf≈1), that will be possible to find a new areas of use of staurolite concentrate as well as the mixtures of staurolite and high-strength diamond powders of the AC200 grade, especially in the grindingcutting and drilling tools.

References

- DuPont (2013) http://www2.dupont.com/

- Marco (2018) http://www.marco.us/abrasives/staurolite

- Texan Stone (2018) https://www.texanstone.com/products##staurolite

- Klein C, Cornelius S, Hurlbut Jr (1985) Manual of Mineralogy, (20th Edn), Wiley, 382-383.

- Lavrinenko VI, Solod VYu, Sytnik BV, Devitskii AA, Nikitin Yu I, et al. (2012) The study of possibility of efficient use of mineral grain concentrates as bearing elements in diamond wheel working layer. Journal of Super hard Materials 34(1): 56-62.

© 2019 Vladimir Poltoratskiy. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)